Application

Pneumatic Tank bottom valve is a pneumaticallyoperated single seat valve which is assembled atthe bottom of tank,

used in diary,food processing,beverage,pharmaceutical and fine chemical industries.

Tank bottom valve is used to vent the containermaterial and the material will not be stuck in thevalve chamber,

the design of the seat open to theinside of the container. It avoids the overvoltagebecause the pipe leads to

the possibility of accidental opening of the valve.

Operating Principle

*Valve structure: Valve seat opens construction inside so that it can avoid pushing when pipeline is over pressure

*Parts in contact with the product :AISI316L,AISI304

*Other part :AISI304

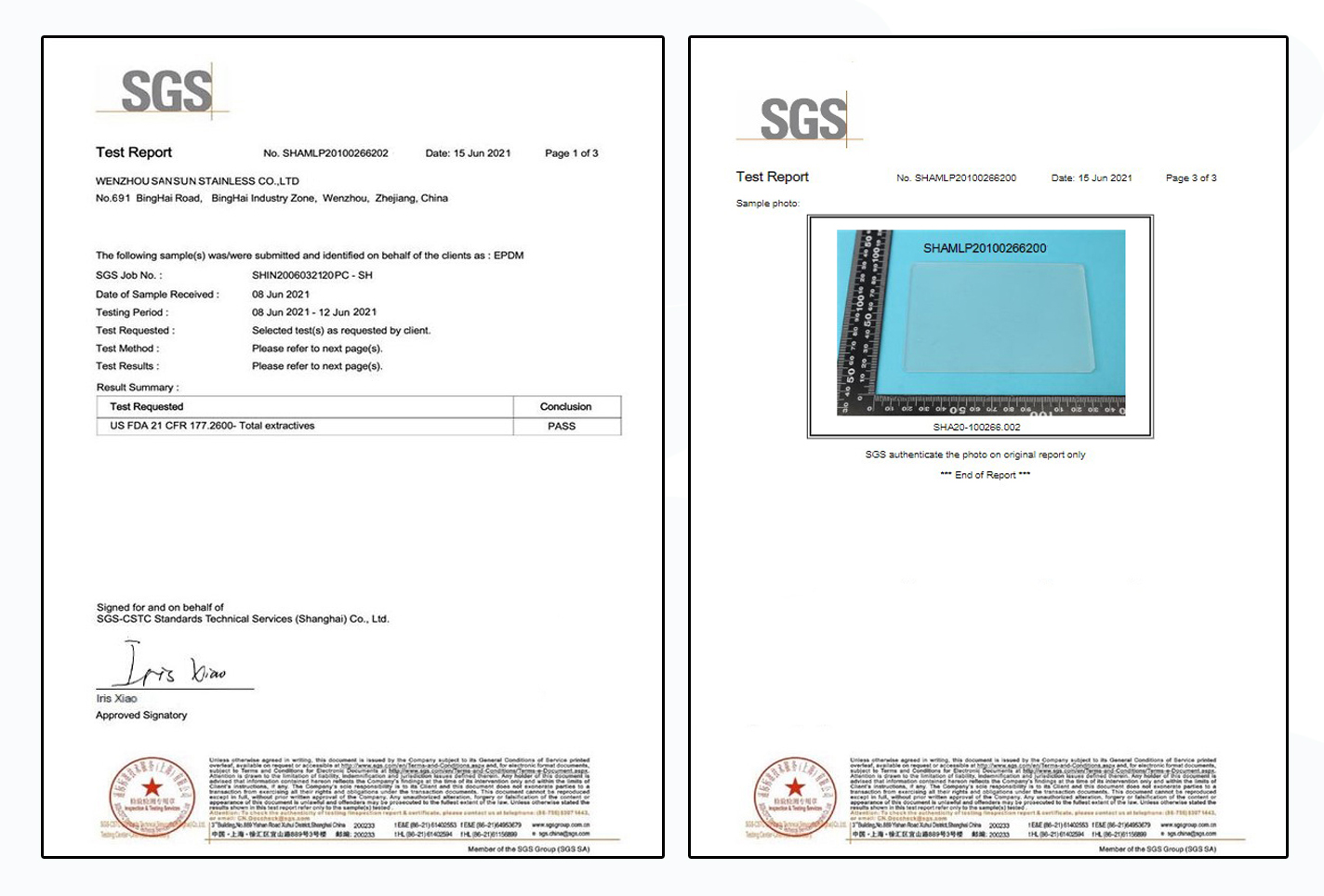

*Gasket(standard):EPDM according to FDA177.2600

*Internal surface finish:Ra≤0.8pm

*External surface finish:Mirror polish

Technical Specification

*Size:DN15-DN100,1/2"-4"

*Working temperature:-25ºC +180ºC (PTFE)

*Max. Working pressure :10 bar/145 psi

*Compressed air pressure:6-8 bar/87-116psi

*Air supply connections:G 1/8"(BSP)

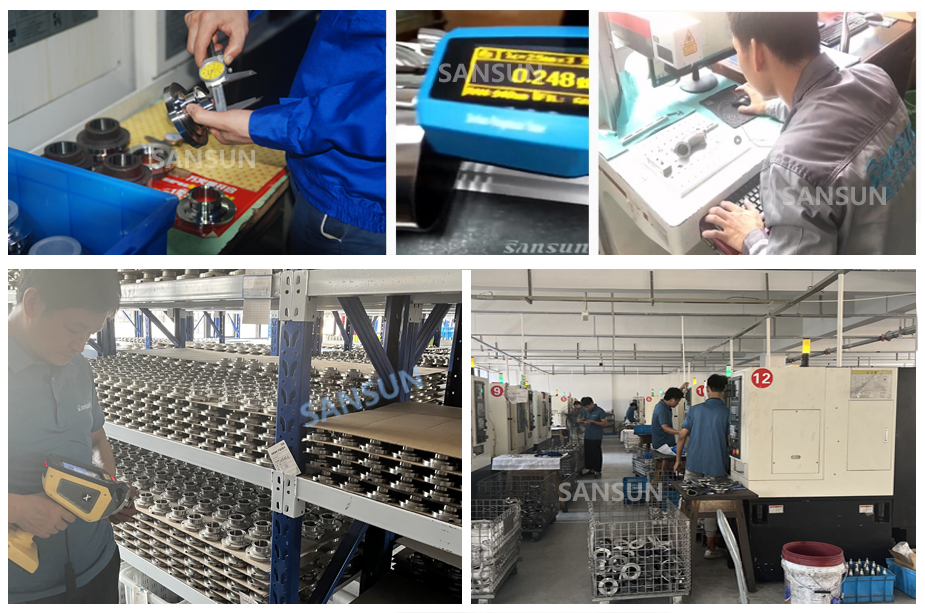

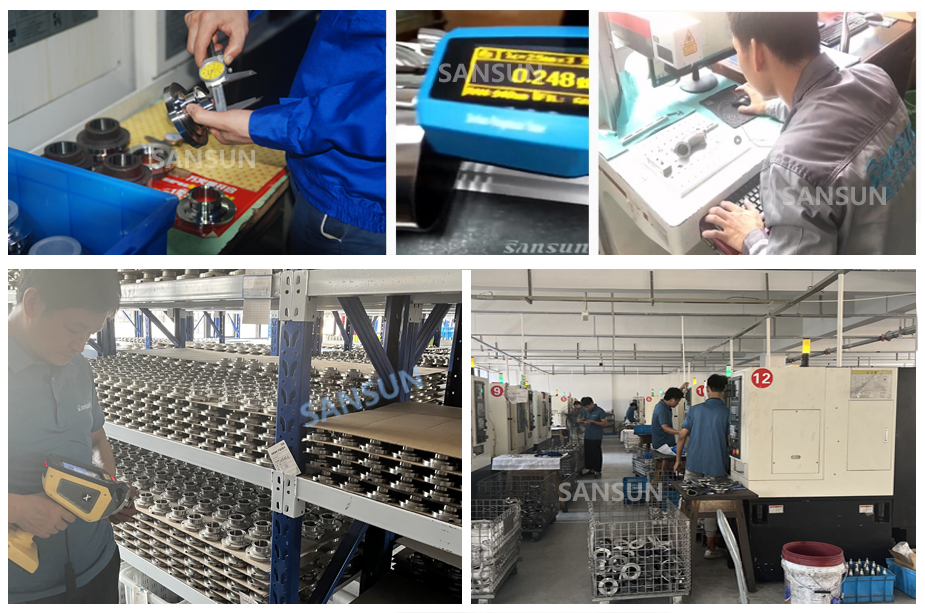

Inspection

All kinds of non-standard products are customized according to the requirements of customers. Products can be traced back to the manufacturing and time of each process to ensure the quality of products.